Frameless vs Framed Cabinets: The 2026 Contractor’s Complete Comparison Guide

When choosing between frameless vs framed cabinets for your next project, understanding the key differences in construction, cost, and functionality is essential for making informed purchasing decisions. Frameless cabinets, also known as European-style or full-access cabinets, eliminate the traditional face frame to maximize storage space and create a sleek, modern aesthetic.

Framed cabinets, the American standard, feature a solid wood face frame that provides structural support and accommodates various door styles. For contractors and builders seeking wholesale frameless cabinets or traditional framed options, this comprehensive guide covers everything from the 32mm system construction to cost comparisons, installation requirements, and the best wholesale cabinet supplier options for 2026 projects.

Key Takeaways

- Frameless cabinets offer 10-15% more interior storage space by eliminating the face frame

- Framed cabinets cost approximately $1,000 less per kitchen and are easier to install

- The 32mm system standardizes frameless cabinet construction for efficient manufacturing

- Frameless cabinets account for 40-45% of the U.S. market, with demand growing in modern kitchen designs

- Wholesale cabinet suppliers like NextDAY Cabinets offer both framed and European frameless design options with 3-5 day delivery

- Blum hinges and soft-close mechanisms are standard in quality frameless cabinet construction

- KCMA certification and CARB Phase 2 compliance indicate quality and environmental standards

What Are Frameless Cabinets?

Frameless cabinets, commonly referred to as European-style cabinets or full-access cabinets, are constructed without a face frame attached to the front of the cabinet box. This construction method originated in Europe after World War II when manufacturers developed the standardized 32mm system to efficiently rebuild homes using engineered wood panels rather than scarce solid lumber. According to Wikipedia’s frameless construction article, this system uses a 32-millimeter spacing between system holes for standardized hardware installation.

The doors and drawers on frameless cabinets attach directly to the cabinet box using concealed European hinges, typically from premium manufacturers like Blum or Hettich. These soft-close hinges offer three-way adjustability (up/down, in/out, side-to-side), making precise door alignment easier after installation. The cabinet box itself uses thicker side panels—typically ¾-inch plywood or high-quality MDF—to compensate for the structural support that would otherwise come from a face frame.

| Feature | Frameless Cabinet Specification |

| Construction Style | European / Full-Access |

| Face Frame | None – doors attach directly to box |

| Side Panel Thickness | ¾ inch (18mm) minimum |

| Hinge Type | Concealed European hinges (Blum, Hettich) |

| Door Overlay | Full overlay only |

| Storage Space | 10-15% more than framed |

| Market Share (2026) | 40-45% of U.S. installations |

| Common Materials | Plywood, MDF, High-Density Fiberboard |

What Are Framed Cabinets?

Framed cabinets, also known as face frame cabinets or American-style cabinets, feature a solid wood frame attached to the front of the cabinet box. This frame consists of horizontal rails and vertical stiles, typically measuring 1½ inches wide and ¾ inch thick. The face frame provides significant structural reinforcement and serves as the mounting surface for door hinges and drawer hardware.

This construction method has been the standard in North American cabinet box construction for generations, representing approximately 55-60% of the current market. The Kitchen Cabinet Manufacturers Association (KCMA) reports that framed cabinets remain the dominant choice for traditional and transitional kitchen designs. Framed cabinets accommodate multiple door styles including partial overlay, full overlay, and inset configurations, offering greater design flexibility for contractors working on diverse projects.

This construction method has been the standard in North American cabinet box construction for generations, representing approximately 55-60% of the current market. The Kitchen Cabinet Manufacturers Association (KCMA) reports that framed cabinets remain the dominant choice for traditional and transitional kitchen designs. Framed cabinets accommodate multiple door styles including partial overlay, full overlay, and inset configurations, offering greater design flexibility for contractors working on diverse projects.

| Feature | Framed Cabinet Specification |

| Construction Style | American / Traditional |

| Face Frame | Solid wood (1½” x ¾”) |

| Side Panel Thickness | ½ inch typical |

| Hinge Type | Surface-mount or concealed |

| Door Overlay Options | Partial, Full, or Inset |

| Storage Space | Standard (face frame reduces access) |

| Market Share (2026) | 55-60% of U.S. installations |

| Common Materials | Solid wood frame, plywood/particleboard box |

Construction Differences: The 32mm System Explained

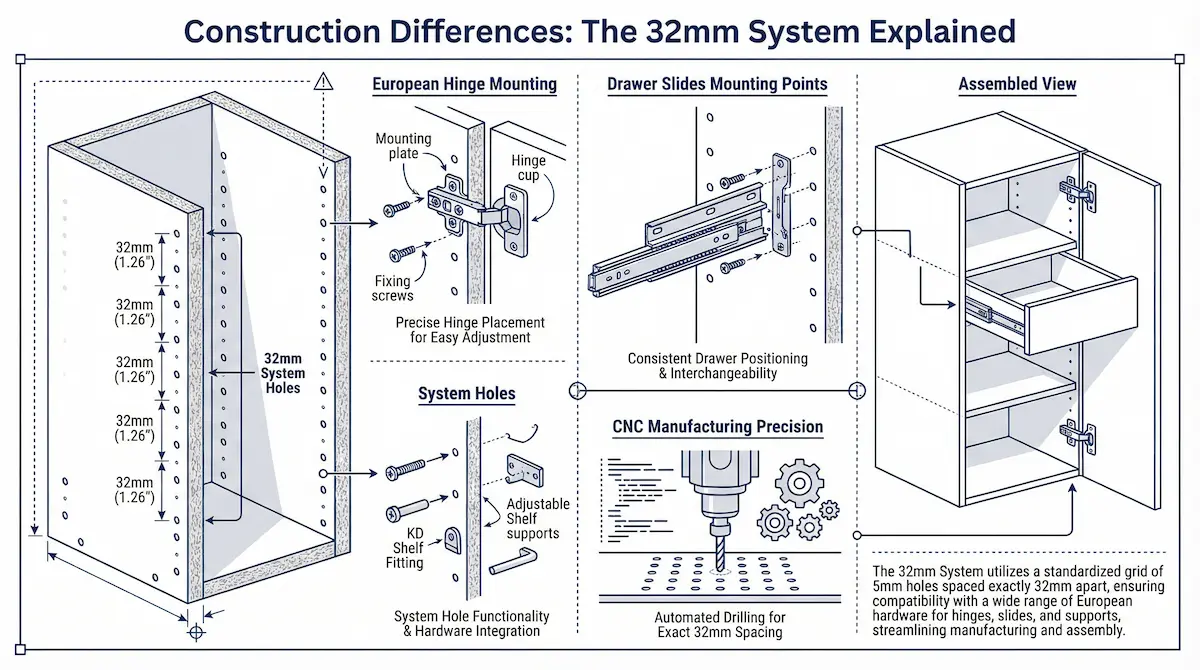

Understanding the construction differences between frameless and framed cabinets is essential for contractors evaluating wholesale frameless cabinets for their projects. The 32mm system (also called the European system or System 32) forms the foundation of modern frameless cabinet manufacturing. This standardized approach uses precisely spaced holes at 32-millimeter intervals along cabinet sides, enabling consistent hardware installation across all cabinet components.

The 32mm System: Manufacturing Efficiency

The 32mm System: Manufacturing Efficiency

The 32mm cabinetmaking system revolutionized cabinet production by enabling CNC manufacturing with standardized tooling. Benefits for frameless cabinet manufacturers include reduced setup time between production runs, interchangeable hardware components from different suppliers, simplified inventory management, faster assembly using standardized jigs, and consistent quality across production batches. This efficiency translates to competitive wholesale pricing for contractors purchasing bulk frameless cabinets.

| Construction Element | Frameless Cabinets | Framed Cabinets |

| Box Material Thickness | ¾” (18mm) | ½” typical |

| Structural Support | Thick side panels | Face frame |

| Hardware Mounting | 32mm system holes | Face frame surface |

| Manufacturing Method | CNC automated | Traditional joinery |

| Assembly Time | Faster (standardized) | Longer (custom fitting) |

| Adjustability | 3-way hinge adjustment | Limited adjustment |

| Edge Finishing | Edge banding required | Frame covers edges |

Frameless vs Framed Cabinets: Side-by-Side Comparison

For contractors comparing frameless vs framed cabinets, this comprehensive comparison addresses the factors most critical to project success: storage efficiency, durability, aesthetics, and installation complexity.

Storage Space and Accessibility

Frameless cabinets provide superior cabinet storage space because no face frame obstructs the opening. Drawers can be built wider—up to 1½ inches more interior width—maximizing usable space. This makes full-access cabinets particularly valuable in compact kitchens, urban apartments, and multi-family housing projects where every inch matters. The full-overlay door design also means easier access to items stored at the back of cabinets.

Durability and Longevity

Both construction methods offer excellent durability when built with quality materials. Framed cabinets benefit from the face frame’s additional structural support, making them more forgiving during installation on uneven walls. Frameless cabinets achieve comparable strength through thicker side panels and modern dovetail drawer construction. Look for KCMA certification as an indicator of quality—certified cabinets must pass rigorous testing for door and drawer operation, finish durability, and structural integrity.

| Factor | Frameless Cabinets | Framed Cabinets | Winner |

| Storage Space | +10-15% interior space | Standard | Frameless |

| Modern Aesthetics | Sleek, seamless lines | Traditional look | Frameless |

| Traditional Aesthetics | Limited style options | Multiple overlay options | Framed |

| Installation Ease | Requires precision | More forgiving | Framed |

| Cost (Average) | $150-$350/linear ft | $100-$300/linear ft | Framed |

| Hinge Adjustment | 3-way adjustable | Limited | Frameless |

| Door Style Options | Full overlay only | Partial, full, inset | Framed |

| Manufacturing Speed | CNC automated | Traditional | Frameless |

Cost Analysis for Contractors and Builders

Understanding the cost implications of frameless vs framed cabinets helps contractors optimize contractor profit margins while meeting client expectations. According to industry data, framed cabinets typically cost about $1,000 less than frameless options for a complete kitchen, primarily due to simpler manufacturing and fewer premium hardware requirements.

Cost Breakdown by Linear Foot

| Cabinet Type | Budget Range | Mid-Range | Premium |

| Frameless Wholesale | $150-$200/LF | $200-$300/LF | $300-$400+/LF |

| Framed Wholesale | $100-$150/LF | $150-$250/LF | $250-$350/LF |

| Installation Labor | $50-$100/LF | $75-$125/LF | $100-$150/LF |

| Total Project (10×10) | $4,000-$6,000 | $6,000-$10,000 | $10,000-$15,000+ |

For contractors seeking the best value, partnering with a reliable wholesale cabinet supplier can reduce costs by 30-50% compared to retail pricing. Wholesale cabinet distributors that maintain strong manufacturer relationships—like the NextDAY Cabinets partnership with Kith Kitchens—offer competitive wholesale pricing strategies with fast cabinet lead times.

Installation Requirements and Best Practices

Installation complexity differs significantly between frameless and framed cabinets. Understanding these differences helps contractors accurately estimate labor costs and set appropriate client expectations.

Installing Framed Cabinets

Framed cabinet installation offers several advantages for contractors. The face frame provides a solid surface for driving screws to connect adjacent cabinets, typically using 2½-inch screws through the frame stiles. This construction is more forgiving on uneven walls because the frame can bridge small gaps. Installation steps include leveling the first cabinet, connecting subsequent cabinets through the face frames, shimming as needed, and attaching to wall studs through the cabinet back.

Installing Frameless Cabinets

Frameless cabinet installation requires greater precision because cabinets connect directly through their side panels using shorter screws (typically 1¼ inch maximum). Without a face frame to hide minor misalignments, every cabinet must be perfectly level and plumb. Key considerations include verifying wall flatness before installation, using a laser level for precise alignment, connecting cabinets with multiple attachment points, and ensuring adequate clearance for full-overlay cabinet doors.

| Installation Factor | Frameless | Framed |

| Skill Level Required | Professional recommended | DIY-friendly |

| Screw Length | 1¼” max | 2½” through frame |

| Alignment Tolerance | Minimal (precise required) | More forgiving |

| Wall Prep Required | Must be flat | Can bridge gaps |

| Time per Cabinet | 20-30 minutes | 15-25 minutes |

| Filler Usage | More fillers needed | Standard fillers |

When to Choose Frameless vs Framed Cabinets

The choice between frameless and framed cabinets depends on project requirements, client preferences, and budget constraints. Here’s a decision framework for contractors:

Choose Frameless Cabinets When:

Choose Frameless Cabinets When:

- The client wants a contemporary kitchen design with clean, seamless lines

- Maximizing cabinet storage space is a priority (small kitchens, urban apartments)

- The project involves multi-family housing where modern aesthetics attract renters

- Clients request slab door cabinets or minimalist kitchen design

- Budget allows for quality European style cabinets with premium hardware

Choose Framed Cabinets When:

Choose Framed Cabinets When:

- The design calls for traditional, transitional, or farmhouse aesthetics

- Inset or partial overlay door styles are specified

- Budget constraints require more affordable options

- Installation conditions include uneven walls or floors

- The project timeline doesn’t allow for precision installation

Wholesale Frameless Cabinets: Finding the Right Supplier

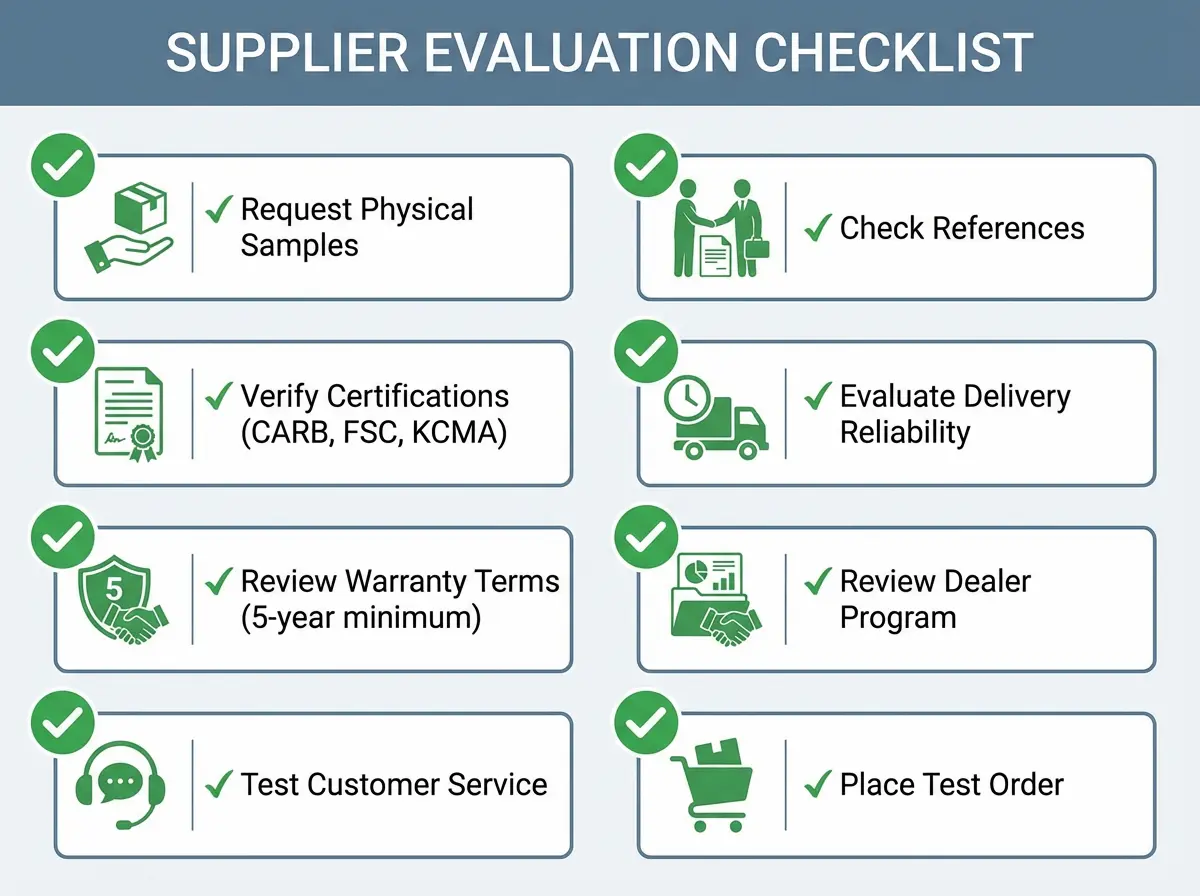

Partnering with the right wholesale cabinet supplier is critical for contractors who need reliable access to both frameless and framed cabinets. Key factors to evaluate include product variety, certifications, lead times, and support services.

Partnering with the right wholesale cabinet supplier is critical for contractors who need reliable access to both frameless and framed cabinets. Key factors to evaluate include product variety, certifications, lead times, and support services.

Essential Supplier Qualifications

Quality wholesale cabinet distributors should offer both construction styles, KCMA certification for quality assurance, CARB Phase 2 compliance for environmental standards, FSC-certified wood options for sustainable projects, Low-VOC finishes meeting LEED requirements, professional 3D kitchen design software and design services, competitive cabinet dealer programs with volume discounts, and fast cabinet lead times (3-5 days for stock items).

| Supplier Feature | Essential | Nice-to-Have |

| KCMA Certification | ✓ Required | – |

| CARB Phase 2 Compliance | ✓ Required | – |

| 3-5 Day Lead Times | ✓ Required | – |

| Free 3D Design Services | – | ✓ Valuable |

| Multiple Showroom Locations | – | ✓ Convenient |

| Dedicated Account Manager | – | ✓ Helpful |

| Volume Discount Programs | ✓ Required | – |

| Low-VOC Finish Options | – | ✓ For green projects |

Source Quality Wholesale Frameless Cabinets from NextDAY Cabinets

For contractors in Virginia, Maryland, and Chicago seeking both wholesale frameless cabinets and quality framed options, NextDAY Cabinets offers a comprehensive solution. Through our exclusive partnership with Kith Kitchens and their 27+ years of custom cabinetry expertise, we deliver industry-leading speed and quality:

- 3-5 day delivery times on in-stock cabinets

- Eudora frameless European platform for modern designs

- Standard Kith and KithOne framed options for traditional projects

- Blum brand soft-close hinges and drawer glides

- KCMA-certified construction across all product lines

- Low-VOC finishes with CARB Phase 2 compliance

- Free professional 3D design services

- Six showroom locations for hands-on product evaluation

Visit one of our showrooms in Alexandria, Beltsville, Chantilly, Richmond, Woodbridge, or Chicago to explore our complete frameless and framed cabinet collections. Our trade specialists can help you select the right construction method for every project while maximizing your contractor profit margins.

Frequently Asked Questions

What is the main difference between frameless and framed cabinets?

Frameless cabinets (European-style) have no face frame—doors attach directly to the cabinet box. Framed cabinets (American-style) feature a solid wood face frame that provides structural support and serves as the hinge mounting surface. This fundamental difference affects storage capacity, aesthetics, installation requirements, and cost.

Are frameless cabinets more expensive than framed cabinets?

Yes, frameless cabinets typically cost 15-20% more than comparable framed options. The price difference stems from thicker materials, premium European hardware (like Blum hinges), and precision manufacturing requirements. However, working with a wholesale cabinet supplier can significantly reduce this cost gap.

What is the 32mm system in cabinet making?

The 32mm system is a standardized construction method for frameless cabinets using holes spaced 32 millimeters apart along cabinet sides. This spacing accommodates standardized European hardware from manufacturers like Blum and Hettich, enabling efficient CNC manufacturing and simplified assembly.

Do frameless cabinets offer more storage space?

Yes, frameless cabinets provide approximately 10-15% more usable interior space compared to framed cabinets. Without the face frame obstructing the opening, drawers can be built wider (up to 1½ inches more), and there’s easier access to items stored at the back of full-access cabinets.

Are frameless cabinets harder to install?

Frameless cabinet installation requires more precision than framed cabinets. Without a face frame to hide minor misalignments, every cabinet must be perfectly level and plumb. Professional installation is recommended, and walls should be checked for flatness before beginning. Framed cabinets are more forgiving and suitable for DIY installation.

Which type of cabinet lasts longer?

Both frameless and framed cabinets can last 20-30+ years when constructed from quality materials. Look for KCMA-certified cabinets, plywood construction (rather than particleboard), and premium hardware like soft-close hinges. Proper installation and maintenance matter more than construction style for longevity.

Can frameless cabinets support granite countertops?

Yes, quality frameless cabinets with ¾-inch plywood construction can support heavy countertops including granite, quartz, and concrete. The thicker side panels in frameless construction actually provide excellent load-bearing capacity. For extra-heavy applications, additional support brackets or a plywood subtop may be recommended.

What should I look for in a wholesale frameless cabinet supplier?

Essential qualifications for a wholesale cabinet supplier include KCMA certification, CARB Phase 2 compliance, competitive wholesale pricing, fast cabinet lead times (3-5 days), professional design services, and strong cabinet dealer programs. Look for suppliers offering both frameless and framed options to serve diverse project needs.

Related Resources