RTA vs Pre-Assembled Cabinets: Cost, Quality & Installation Compared

Choosing between RTA vs pre-assembled cabinets is one of the most impactful decisions you will make during a kitchen remodel. RTA cabinets (ready to assemble cabinets) arrive flat-packed with pre-cut panels, pre-drilled holes, and all necessary hardware, requiring on-site assembly before installation. Pre-assembled kitchen cabinets, on the other hand, come fully built from the factory and are ready for immediate installation. The cost difference is significant: RTA cabinets typically save homeowners and contractors 20–50% compared to their pre-assembled counterparts.

A standard 10×10 kitchen can cost between $1,200 and $4,400 with flat pack cabinets, while the same layout in pre-assembled options runs $300 to $1,000 more. Beyond price, factors like assembly time, cabinet durability, cabinet construction methods, shipping logistics, and long-term quality all play a role in this decision. Whether you are a homeowner planning a DIY kitchen remodel, a contractor managing multiple jobsites, or a builder sourcing wholesale kitchen cabinets in bulk, this comprehensive guide breaks down every angle of the RTA cabinets pros and cons versus pre-built kitchen cabinets debate so you can choose the right option for your project.

Key Takeaways

- RTA cabinets cost 20–50% less than pre-assembled cabinets, making them ideal for budget-conscious kitchen renovation projects.

- Pre-assembled kitchen cabinets eliminate assembly time completely, arriving ready to install straight from the manufacturer.

- RTA cabinet assembly takes 15–45 minutes per unit depending on experience, while pre-assembled options need zero assembly labor.

- Both cabinet types can last 20–30 years when made from solid wood or plywood and properly installed.

- Flat pack cabinets reduce shipping costs by 30–50% due to compact packaging and lower freight volume.

- Pre-assembled cabinets offer wider customization including built-in wine racks, pull-outs, lazy Susans, and custom configurations.

- Contractors working on tight deadlines often prefer pre-assembled cabinets to reduce on-site labor hours.

- KCMA certified cabinets, whether RTA or assembled, meet rigorous quality and durability standards.

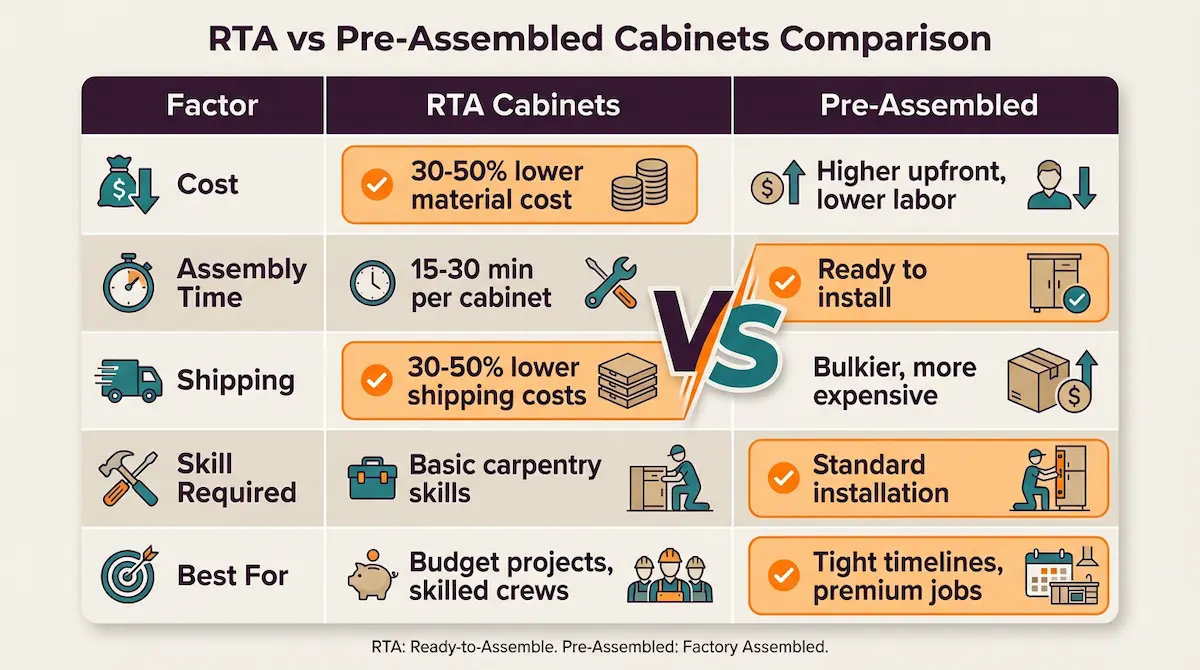

RTA vs Pre-Assembled Cabinets at a Glance

Before diving into the details, here is a quick visual comparison to help you see the main differences between these two popular kitchen cabinet types at a glance:

| Feature | RTA Cabinets | Pre-Assembled Cabinets |

| Average Cost (10×10) | $1,200–$4,400 | $1,500–$5,400 |

| Assembly Time/Unit | 15–45 minutes | None (ready to install) |

| Shipping Method | Flat pack / compact boxes | Bulky / full-size packaging |

| Delivery Lead Time | 1–3 weeks | 3 weeks–3 months |

| Shipping Cost | 30–50% lower | Higher (bulkier packaging) |

| Customization | Standard sizes, growing options | Semi-custom & fully custom available |

| Best For | Budget-focused, DIY, bulk orders | Tight timelines, complex designs |

| Durability (Premium) | 20–30 years | 20–30 years |

| Damage Risk in Transit | Lower (compact packaging) | Higher (exposed components) |

1. What Are RTA Cabinets and Pre-Assembled Cabinets?

Understanding the fundamental difference between ready to assemble cabinets and pre-assembled kitchen cabinets is the first step toward making a confident purchasing decision. While the names are somewhat self-explanatory, the distinctions go deeper than just how the product arrives at your doorstep.

Understanding the fundamental difference between ready to assemble cabinets and pre-assembled kitchen cabinets is the first step toward making a confident purchasing decision. While the names are somewhat self-explanatory, the distinctions go deeper than just how the product arrives at your doorstep.

What Are RTA Cabinets?

RTA cabinets — which stands for Ready-to-Assemble — are kitchen and bathroom cabinetry units shipped unassembled in compact, stackable flat pack cabinets boxes. Each package includes pre-cut panels with precision-drilled holes, all required hardware such as screws, cam lock assembly connectors, brackets, and soft-close hinges, along with detailed assembly instructions. Many manufacturers also provide assembly tutorial videos. The construction materials vary by brand and price tier, ranging from particleboard at the budget end to solid plywood cabinet box construction and genuine hardwood face frames at the premium level. Modern high-quality RTA cabinets often feature dovetail drawer construction and dovetail joint techniques that rival the structural integrity of their factory-assembled counterparts.

What Are Pre-Assembled Cabinets?

Pre-assembled kitchen cabinets arrive from the manufacturer fully built and ready for installation. Doors are hung, drawers are fitted, and hardware is installed — all you need to do is mount them. These cabinets are assembled in a factory environment using industrial-grade tools, adhesives, and quality control processes. This professional assembly ensures consistent construction across every unit. Pre-assembled options range from stock models with standard configurations to semi-custom and fully custom designs that are manufactured to your exact specifications, allowing for specialized features like built-in wine storage, mixer lifts, blind corner swing-outs, and integrated lighting. Reputable pre-assembled cabinet lines often carry KCMA certification from the Kitchen Cabinet Manufacturers Association, signifying that they have passed rigorous performance testing for structural integrity, drawer functionality, and finish durability.

| Attribute | RTA Cabinets | Pre-Assembled Cabinets |

| Arrives As | Flat-packed, unassembled | Fully built, ready to install |

| Assembly Required | Yes (on-site) | No |

| Common Materials | Plywood, MDF, solid wood | Plywood, MDF, solid wood |

| Hardware Included | Yes (in box) | Yes (pre-installed) |

| KCMA Certification | Available on premium lines | More commonly certified |

2. Cost Comparison: RTA vs Pre-Assembled Cabinets

Price is often the most decisive factor in the RTA vs pre-assembled cabinets debate, and the savings with RTA options are substantial. The cost advantage of ready to assemble cabinets stems from two primary factors: eliminated factory assembly labor and dramatically reduced shipping expenses.

For a standard 10×10 L-shaped kitchen requiring approximately 12 cabinets, RTA cabinets typically cost between $1,200 and $4,400 at the wholesale level. The same kitchen configured with pre-assembled kitchen cabinets will run anywhere from $1,500 to $5,400, with the premium driven by factory assembly labor costs and significantly higher shipping expenses. For context, semi-custom cabinets cost $150–$650 per linear foot, while assembled cabinets cost roughly $100–$300 per linear foot. Meanwhile, RTA options can start as low as $60 per linear foot for budget-tier products, making them the most accessible entry point for a kitchen remodel budget-conscious project.

The shipping cost differential is equally significant. Because flat pack cabinets occupy a fraction of the freight volume compared to fully assembled units, shipping costs drop by 30–50%. This makes bulk cabinet ordering especially economical for contractors and builders managing multiple projects. Many wholesale kitchen cabinets distributors pass these logistics savings directly to the buyer, resulting in lower per-unit costs that compound into major savings across large-scale projects.

| Cost Category | RTA Cabinets | Pre-Assembled Cabinets |

| Per Linear Foot | $60–$300 | $100–$650 |

| 10×10 Kitchen Average | $1,200–$4,400 | $1,500–$5,400 |

| Shipping Costs | 30–50% lower | Standard (higher freight) |

| Assembly Labor | $0 (DIY) or $50–$100/unit | Included in price |

| Total Savings Potential | 20–50% vs. pre-assembled | Baseline comparison |

3. Quality and Durability: Which Cabinets Last Longer?

A common misconception is that RTA cabinet quality is inherently inferior to pre-assembled alternatives. In reality, both kitchen cabinet types can deliver exceptional durability when manufactured with quality materials. The critical difference lies not in the delivery format but in the construction specifications, material choices, and — for RTA — the quality of on-site assembly.

Premium ready to assemble cabinets from reputable manufacturers use the same materials you find in high-end pre-assembled lines: solid plywood cabinet box construction (typically 1/2″ to 3/4″ Grade-A plywood), hardwood face frames from species like birch, maple, or oak, and dovetail drawer construction for superior joint strength. Soft-close hinges from industry-leading brands like Blum are now standard in many quality RTA lines, eliminating the slamming-door issue that once plagued budget cabinetry. Low-VOC finishes and CARB Phase 2 Compliance for emissions standards are increasingly common across both categories, ensuring healthier indoor air quality.

Premium ready to assemble cabinets from reputable manufacturers use the same materials you find in high-end pre-assembled lines: solid plywood cabinet box construction (typically 1/2″ to 3/4″ Grade-A plywood), hardwood face frames from species like birch, maple, or oak, and dovetail drawer construction for superior joint strength. Soft-close hinges from industry-leading brands like Blum are now standard in many quality RTA lines, eliminating the slamming-door issue that once plagued budget cabinetry. Low-VOC finishes and CARB Phase 2 Compliance for emissions standards are increasingly common across both categories, ensuring healthier indoor air quality.

Pre-assembled cabinets do hold an edge in construction consistency. Factory assembly uses industrial-grade pneumatic tools, precision jigs, and adhesives that create joints stronger than what most on-site assembly can replicate. Cabinets carrying KCMA certification have passed standardized tests for structural integrity, door and drawer operation, and finish resistance to stains, chemicals, and heat. Both Forevermark Cabinets and Wolf Classic Cabinets are examples of KCMA-certified pre-assembled lines that combine affordability with verified quality. When properly installed, high-quality cabinets from either category can last 20–30 years, making cabinet material comparison and construction methods more important than the assembled-versus-RTA distinction alone.

| Quality Factor | RTA Cabinets | Pre-Assembled Cabinets |

| Box Material (Premium) | 3/4″ plywood | 3/4″ plywood |

| Drawer Construction | Dovetail or cam lock | Dovetail (standard in most) |

| Hinge Quality | Soft-close (premium lines) | Soft-close (standard) |

| Finish Durability | UV-cured, low-VOC available | Factory UV-cured, low-VOC |

| Assembly Consistency | Varies (user-dependent) | High (factory-controlled) |

| Expected Lifespan | 20–30 years (quality tier) | 20–30 years |

4. Assembly Time and Installation Requirements

The cabinet assembly time difference between RTA and pre-assembled options is one of the most practical considerations, especially for professionals managing project timelines. Understanding the real-world labor requirements helps you accurately calculate project costs and set realistic completion schedules.

For RTA cabinets, manufacturers generally estimate 15 minutes per cabinet for experienced assemblers and 35–45 minutes per unit for beginners. This means a typical 10×10 kitchen with 12 cabinets requires approximately 3–4 hours of assembly labor for a skilled contractor, or 7–9 hours for a first-timer. The RTA cabinet assembly tools needed are basic: a cordless drill, screwdriver, rubber mallet, wood glue, tape measure, level, and clamps. Pre-drilled holes and cam lock assembly systems simplify the process significantly, but attention to detail is essential. Misaligned panels can result in doors that do not close flush, drawers that stick, and overall structural weakness. If you are not confident in your assembly skills, many kitchen cabinet suppliers offer professional assembly services for an additional $50–$100 per cabinet.

Pre-assembled kitchen cabinets bypass the assembly step entirely. They arrive ready for cabinet installation directly onto the wall. For contractors, this translates to faster jobsite turnaround and reduced labor costs. On a multi-unit construction project, eliminating assembly across dozens or hundreds of cabinets can save days of on-site labor, a benefit that often offsets the higher per-unit cost of pre-assembled options.

| Installation Factor | RTA Cabinets | Pre-Assembled Cabinets |

| Assembly Time (Expert) | 15 min/cabinet | 0 min (none required) |

| Assembly Time (Beginner) | 35–45 min/cabinet | 0 min |

| 10×10 Kitchen Total Labor | 3–9 hours assembly + install | Install only (2–4 hours) |

| Tools Required | Drill, mallet, glue, level | Drill, level, stud finder |

| Skill Level Needed | Basic to intermediate DIY | Basic installation skills |

5. Shipping, Delivery, and Lead Times

The logistics of getting cabinets to your project site differ dramatically between RTA and pre-assembled options, and these differences have a direct impact on your cabinet lead time, project scheduling, and overall budget.

Flat pack cabinets offer significant logistics advantages. Their compact packaging means more units fit on a single truck, shipping costs are lower, and the risk of transit damage is reduced because components are securely nested inside flat boxes rather than exposed as bulky assembled units. Most RTA suppliers maintain in-stock inventory, enabling lead times of just 1–3 weeks. Some wholesale distributors offer even faster turnaround — NextDAY Cabinets, for example, provides 3–5 day delivery on many in-stock cabinet lines. This speed advantage makes RTA particularly attractive for contractor cabinet purchasing when project timelines are tight and delays are costly.

Pre-assembled kitchen cabinets typically require longer lead times, ranging from 3 weeks for stock models to 3 months or more for semi-custom and custom configurations. The longer wait is driven by manufacturing queues, custom finishing processes, and the logistical challenge of shipping bulky, fully assembled units. The larger package footprint increases freight costs and introduces greater risk of shipping damage prevention challenges — doors can be scratched, frames can be dented, and drawers can shift during transit. Reputable suppliers use protective packaging and inspect units before shipment, but the inherent risk is higher than with compact flat-pack shipments.

| Shipping Factor | RTA Cabinets | Pre-Assembled Cabinets |

| Packaging | Flat-pack, compact boxes | Full-size, bulky |

| Typical Lead Time (Stock) | 1–3 weeks | 3–6 weeks |

| Custom Order Lead Time | 2–4 weeks | 6–12 weeks |

| Transit Damage Risk | Low | Moderate to High |

| Freight Cost | 30–50% lower | Standard/higher |

6. Customization Options and Design Flexibility

When it comes to cabinet door styles, finishes, and specialized configurations, both cabinet categories offer extensive choices, though pre-assembled cabinets traditionally hold the edge in deep customization.

Ready to assemble cabinets have come a long way in terms of design variety. Modern RTA lines offer popular shaker cabinets, flat-panel contemporary styles, raised-panel traditional looks, and even glass-front options. Finish selections now span white, gray, espresso, navy, natural wood tones, and more. Cabinet hardware quality has also improved dramatically, with soft-close hinges, full-extension drawer glides, and adjustable shelf clips standard on many premium RTA lines. However, RTA customization is generally limited to standard sizes and pre-configured layouts.

Pre-assembled cabinets offer deeper customization, especially in semi-custom and custom tiers. You can specify exact dimensions, choose from hundreds of door and finish combinations, and incorporate specialized features like built-in wine racks, pull-out trash centers, appliance garages, and corner lazy Susans. Manufacturers like Kith Kitchens, with over 27 years of custom cabinetry expertise, offer product lines ranging from the budget-friendly KithOne series all the way to the ultra-premium Mouser Cabinetry line, giving trade professionals access to virtually unlimited design possibilities. Both Shaker style and modern frameless European designs are available across the spectrum.

| Design Feature | RTA Cabinets | Pre-Assembled Cabinets |

| Door Styles | Shaker, flat-panel, raised-panel | All styles + custom profiles |

| Finish Options | 10–30 colors per brand | 50–200+ options (semi-custom) |

| Custom Sizing | Limited (standard increments) | Available (exact dimensions) |

| Specialty Features | Add-on upgrades available | Built-in wine racks, pull-outs, etc. |

| Framed vs Frameless | Both available | Both available |

7. Which Cabinet Type Is Best for Contractors and Builders?

For trade professionals, the RTA vs pre-assembled cabinets decision often comes down to project volume, timeline constraints, and profit margin targets. Both options have compelling advantages when viewed through the lens of contractor cabinet purchasing strategies.

Contractors managing high-volume, budget-driven projects like multi-family housing, rental property flips, or apartment renovations often gravitate toward wholesale RTA cabinets for builders. The per-unit savings of 20–50% compound into substantial margin improvements across a portfolio of projects. With bulk cabinet ordering discounts from wholesale suppliers, trade professionals can access premium solid wood construction at prices that compete with big-box store particleboard options. The compact shipping footprint also simplifies jobsite logistics — a stack of flat-pack boxes is far easier to store in a garage or staging area than a fleet of fully assembled cabinets.

On the other hand, contractors working on custom homes, high-end renovations, or projects with aggressive timelines may find that pre-built kitchen cabinets are worth the premium. Eliminating on-site assembly hours can be the difference between meeting a completion deadline and incurring costly delays. According to the NKBA (National Kitchen & Bath Association), kitchen renovations are among the most timeline-sensitive residential projects, and the ability to install cabinets immediately upon delivery can accelerate the entire project sequence from countertop templating through final trim work. The option to mix RTA and pre-assembled units within a single project offers additional flexibility — use pre-assembled for complex corner units and visible focal points, and RTA for standard base and wall cabinets where assembly is straightforward.

| Project Type | Best Option | Key Reason | Savings Potential |

| Multi-Family / Bulk | RTA Cabinets | Maximum cost savings per unit | 30–50% |

| Custom Homes | Pre-Assembled | Design flexibility & premium finish | N/A (value-driven) |

| Rental Property Flips | RTA Cabinets | Fast turnaround, budget focus | 20–40% |

| Tight-Deadline Remodels | Pre-Assembled | Zero assembly time | Time savings (days) |

| Mixed / Hybrid Projects | Both (Mix & Match) | Optimize budget + timelines | Varies |

8. How to Choose the Right Cabinets for Your Kitchen Remodel

Deciding between RTA vs pre-assembled cabinets is not a one-size-fits-all answer. The right choice depends on your specific project requirements, budget, skills, and timeline. Here is a practical decision framework to guide your selection based on the most common kitchen renovation cost and project scenarios.

Choose RTA cabinets if: your primary goal is maximizing the budget, you or your contractor are comfortable with basic assembly, your project timeline allows 3–9 hours of assembly labor for a standard kitchen, you want fast delivery (many RTA lines ship in 1–3 weeks or less), or you are working on a DIY kitchen remodel and enjoy hands-on involvement. RTA is also the smart choice for investment properties, rental units, and any project where best cabinets for kitchen remodel on a budget is the priority.

Choose pre-assembled cabinets if: you need complex custom configurations that are not available in standard RTA sizes, your project timeline is extremely tight and eliminating assembly labor is critical, you want the assurance of factory-controlled construction quality for every unit, or you are working on a high-end renovation where design details and premium finishes are the priority. Pre-assembled is also ideal if the cabinet warranty and guaranteed structural consistency are deciding factors for your client.

| Your Priority | Best Choice | Why |

| Lowest upfront cost | RTA Cabinets | 20–50% savings on materials |

| Fastest installation | Pre-Assembled | Zero assembly time on site |

| Maximum customization | Pre-Assembled (Custom) | Unlimited size, style, feature options |

| Fastest delivery | RTA Cabinets | In-stock, ships in days |

| Bulk/multi-unit projects | RTA Cabinets | Volume discounts + low shipping |

| High-end client remodel | Pre-Assembled | Premium finish + factory consistency |

For an authoritative overview of cabinet construction standards and history, the Wikipedia article on kitchen cabinets provides useful background context. Additionally, industry research from the NKBA 2025 Kitchen Trends Report highlights how both RTA and pre-assembled cabinetry continue to evolve in terms of sustainability, technology, and design innovation.

9. NextDAY Cabinets: Your Wholesale Source for Both RTA and Assembled Cabinets

When it comes to finding the right wholesale kitchen cabinets for your project, NextDAY Cabinets offers a unique combination of speed, quality, and value that sets us apart in the 2026 market. As a leading wholesale distributor serving contractors, builders, and dealers across Virginia, Maryland, and the greater Chicago area, NextDAY provides both RTA and pre-assembled cabinet options from top manufacturers.

Through our exclusive partnership with Kith Kitchens and their 27+ years of custom cabinetry expertise, we deliver four distinct product lines — KithOne, Standard Kith, Eudora, and Mouser Cabinetry — spanning from budget-friendly entry-level to ultra-premium custom designs. Our cabinet lineup also features Forevermark Cabinets and Wolf Classic Cabinets, both KCMA-certified and assembled in America. Every product line meets CARB Phase 2 Compliance standards and features low-VOC finishes for healthier indoor environments.

With industry-leading 3–5 day delivery on in-stock items, free 3D kitchen design services, showroom locations in Alexandria, Beltsville, Chantilly, Richmond, and Chicago, plus competitive wholesale kitchen cabinets pricing with volume discounts, NextDAY Cabinets is the smart choice for trade professionals who need quality cabinetry delivered fast. Whether you choose RTA for maximum savings or pre-assembled for turnkey convenience, our team is here to support your project from design to delivery.

10. FAQ: RTA vs Pre-Assembled Cabinets

Here are the most frequently asked questions about choosing between RTA vs pre-assembled cabinets:

Are RTA cabinets as good as pre-assembled cabinets?

Yes, when made from premium materials like solid plywood and hardwood face frames, RTA cabinets can match or exceed the quality of many pre-assembled lines. The key factor is the material specification and proper assembly — not the delivery format. Look for KCMA certification and dovetail drawer construction as quality indicators.

How much cheaper are RTA cabinets than pre-assembled?

RTA cabinets typically cost 20–50% less than comparable pre-assembled cabinets. For a standard 10×10 kitchen, this translates to savings of $300 to $1,000 or more, depending on the material tier and brand. The savings come from eliminated factory assembly labor and reduced shipping costs.

How long does it take to assemble RTA cabinets?

An experienced assembler can put together one RTA cabinet in 15–20 minutes. Beginners should plan for 35–45 minutes per unit for the first few cabinets, with speed increasing as you become familiar with the process. A full 10×10 kitchen takes approximately 3–9 hours of assembly time.

What tools do I need to assemble RTA cabinets?

The basic tools required include a cordless drill, screwdriver, rubber mallet, wood glue, tape measure, level, and clamps. Some assemblers also find a stud finder and a right-angle clamp helpful for ensuring square, level construction.

Do RTA cabinets come with all necessary hardware?

Yes, reputable RTA cabinet manufacturers include all necessary hardware in the box: screws, cam locks, brackets, hinges, drawer glides, and assembly instructions. Many premium lines also include pre-attached soft-close hinges and full-extension drawer glides.

Are pre-assembled cabinets worth the extra cost?

Pre-assembled cabinets are worth the investment when your project demands zero assembly time, complex custom configurations, or guaranteed factory-controlled construction quality. They are especially valuable for contractors on tight deadlines and for high-end projects where premium finish and consistency are paramount.

Can I mix RTA and pre-assembled cabinets in the same kitchen?

Absolutely. Many contractors and homeowners use pre-assembled cabinets for complex corner units, islands, and visible focal-point areas while using RTA cabinets for standard base and wall units. This hybrid approach optimizes both budget and timeline.

Which cabinet type is best for contractors working on multiple projects?

For high-volume, budget-driven projects, RTA cabinets offer the best cost savings and shipping efficiency through bulk ordering. For custom homes and tight-deadline renovations, pre-assembled cabinets reduce on-site labor. Many wholesale suppliers like NextDAY Cabinets offer both options with competitive trade pricing.